Repair Of Damage At Laterally Diverted Tendons

This issue can arise when spalled or ruptured concrete is found to exist at a location where there is a lateral change in the direction of an unbonded tendon span. The tendons may have ruptured from the structure as the result of concrete spalling, due to corrosion of embedded reinforcing steel, or because of insufficient hairpin reinforcement within the damaged area. While some may find it tempting to make the repair within the existing damaged area of the slab (and where the tendons are making the lateral directional change), this should be avoided for several reasons.

Structural considerations at laterally swept tendon locations

The standard vertical tendon profile as it runs along its length may be either higher or lower in the concrete, depending on the bending or shear moments at a particular point. This profile is readily accommodated within the concrete member and is rarely cause for concern unless there are large sections of concrete that need to be removed.

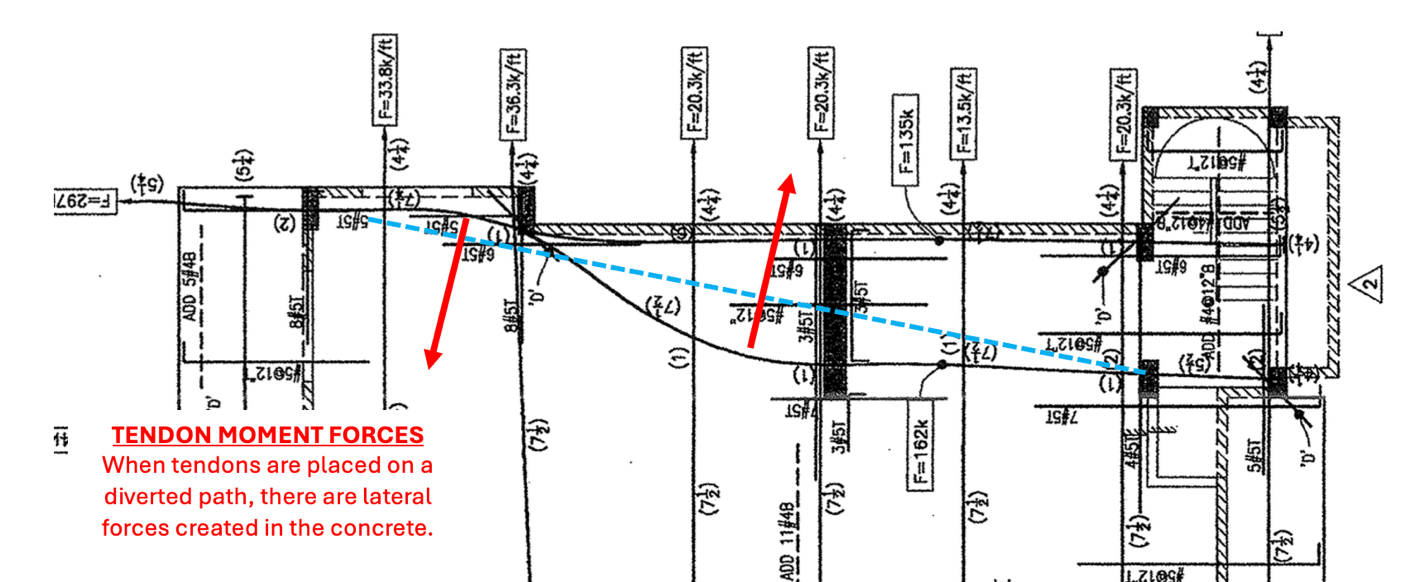

However, a tendons linear profile presents different challenges and is the subject of this discussion. When tendons are placed on a laterally diverted path, there are horizontal forces created in the concrete that must be recognized and accounted for, prior to undertaking any repair of the damaged area.

Hairpin Reinforcement

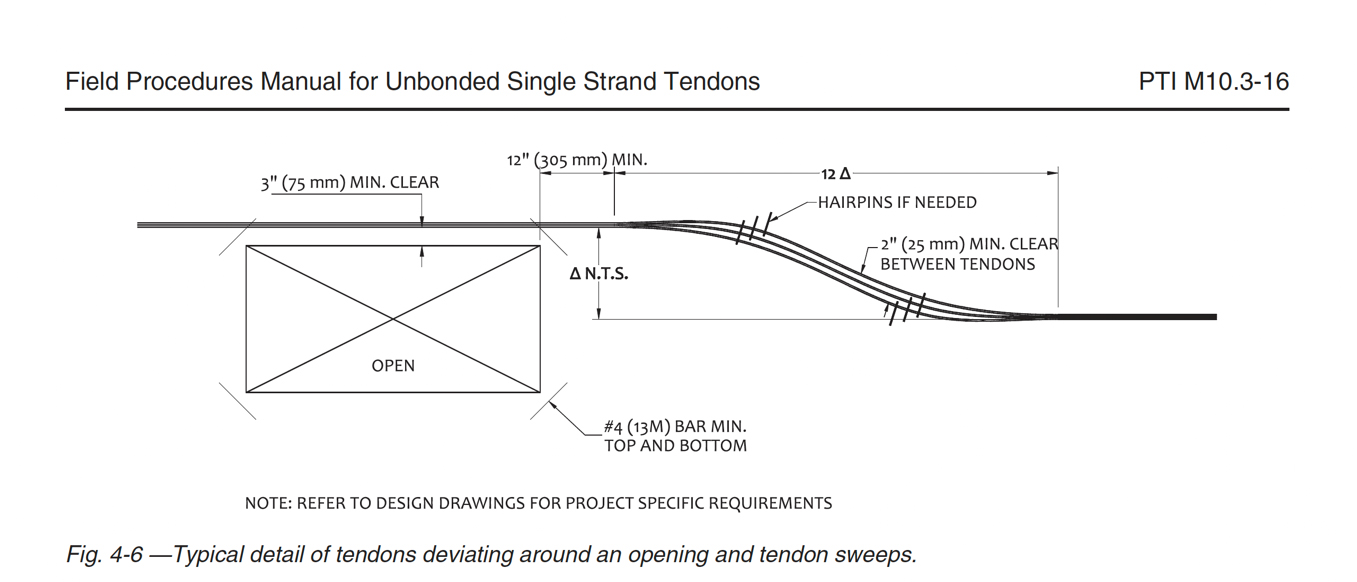

It has been observed that a common cause of tendons rupturing from a slab is due to a lack of adequate mild reinforcement in the form of hairpins that constrain the horizontal shear forces. This is particularly an issue with large groups of bundled cables but can develop with unreinforced single tendon sweeps. If it has been determined that insufficient hairpin reinforcement exists using non-destructive investigative means, such as X-ray or Ground Penetrating Radar, then this needs to be rectified as part of the overall repair strategy. While repair options may be considered, such as the installation of carbon fiber reinforcement to the slab surface, or vertically oriented rebar dowels along the tendon run, they should be thoroughly assessed by the structural engineer. It has been found that these alternatives often prove to be either structurally inadequate, or procedurally unsafe to be used. This often leaves the excavation of concrete from the lateral sweep area and replacement with rebar hairpins as the best alternative. It should be recognized that this repair option can be difficult because it will require the release of tension on all tendons with the repair location, and there may be large sections of concrete that need to be removed. Additionally, the installation of structural shoring in the areas that have temporarily lost post-tensioning support will need to be addressed.

Image: Plan view sketch showing lateral tendon force in slab structure.

Danger of inadequately reinforced tendons adjacent to damaged area

Prior to undertaking any repair efforts, it should be determined what post-tensioning exists within close proximity of the damaged area, and if these tendons also lack proper hairpin reinforcement, as they too could rupture from the slab during the repair. A failure of this type can present a significant safety hazard to anyone close by, as well as a potential loss of post-tensioning that can affect an entire tendon span. An examination of available structural and/or post-tension shop drawings can help identify the full extent of post-tensioning in the effected area. Additionally, it can be helpful to x-ray the areas around the damaged slab in order to confirm the existence and location of all post-tensioning and hairpin reinforcement that will play a factor in the repair.

Image: The Post-Tensioning Institute recognizes the need for additional mild reinforcement in lateral sweeps.

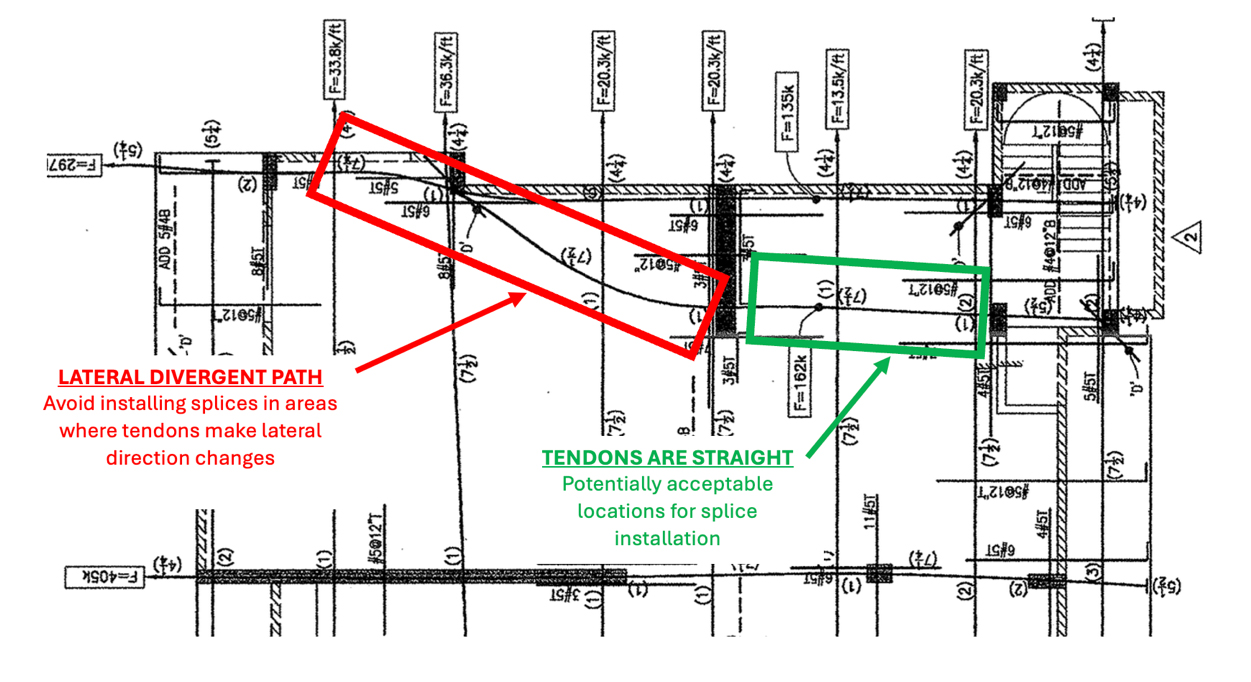

Splice Coupler placement within a lateral tendon sweep

An issue that should be avoided is the installation of splice couplers at a location that places high bending stress on the hardware. These parts are designed to handle high tension loads that run in a straight unidirectional manner through the part. When they are subjected to off-center excentric tension loads, it can overstress the hardware and result in a sudden and catastrophic failure of the splice coupler. It is strongly recommended to avoid the installation of splices within an area of lateral tendon displacement. Instead, they should be located where the tendons have returned to a straight configuration.

Photo: Installation of these splice couplers within the tendon sweep places an excentric load on the hardware.

Image: Sketch shows locations to avoid when installing splice couplers.

Conclusion

Damage located within a lateral sweep of the tendons can be very challenging and should be approached with the utmost of due diligence and consideration. These repairs can evolve into complex and costly projects once the full extent of the concrete damage, tendon damage, mild steel reinforcement deficiencies, and repair alternatives are taken into consideration. Overlooking the underlying nature of the damage and rushing into a quick repair can threaten the safety of the technicians involved in the repair, as well as the structural integrity of the building.

Cited References/Images

PTI M-10: Unbonded Tendon Committee, “Field Procedures Manual for Unbonded Single Strand Tendons (PTI M10.3-16),” Post-Tensioning Institute, Farmington Hills, MI, 2016, 15pp.

For more information:

Please email us at info@GenBuild.net

Click below the link to download the pdf file: