Post-tensioned Repair Bid Document Problems & Solutions

Introduction

With over three decades experience in post-tensioned structural repairs, we have observed that there is an issue which continues to plague our industry; and that is the problem of poorly prepared bid documentation. The contracting process for most projects begins with the development and issuance of plans, specifications, and a bid form that are intended to provide all involved parties with a clear understanding as to the scope and requirements for the project. It should be obvious that the thoroughness of these bid documents can determine the success or failure of a project, but we routinely find that many specifiers don’t seem to have an adequate understanding of the requirements necessary to perform the post-tensioned scope of work. Documents that contain inconsistencies or that lack clarity and specificity can lead to problems that arise during both the bid and execution phases of the project. This usually results from confusion and misunderstandings regarding the actual scope of work that is required, which can lead to inconsistent bid results, inaccurate project budgeting, or conflict between the parties.

It begins with a damage survey

Given that we’re addressing the repair of damaged post-tensioned structures, the logical place to begin is with an assessment of the building conditions and how this damage relates to the existing post-tensioning. For example, much of the corrosion damage to the mild steel reinforcement in elevated slabs can be anticipated to involve post-tensioning terminal anchorages located at the slab edges, or where concrete spalling has exposed the post-tensioning somewhere along the tendon span length. Most concrete damage conditions will usually involve only a few typical, but distinct post-tensioning repair scopes of work. The specifier should familiarize themselves with these common post-tension repair protocols and use the visible concrete damage locations to correlate the type and quantity of post-tension repair techniques necessary to address the damage that has been observed.

Using post-tension shop drawings and structural plans for the damage evaluation

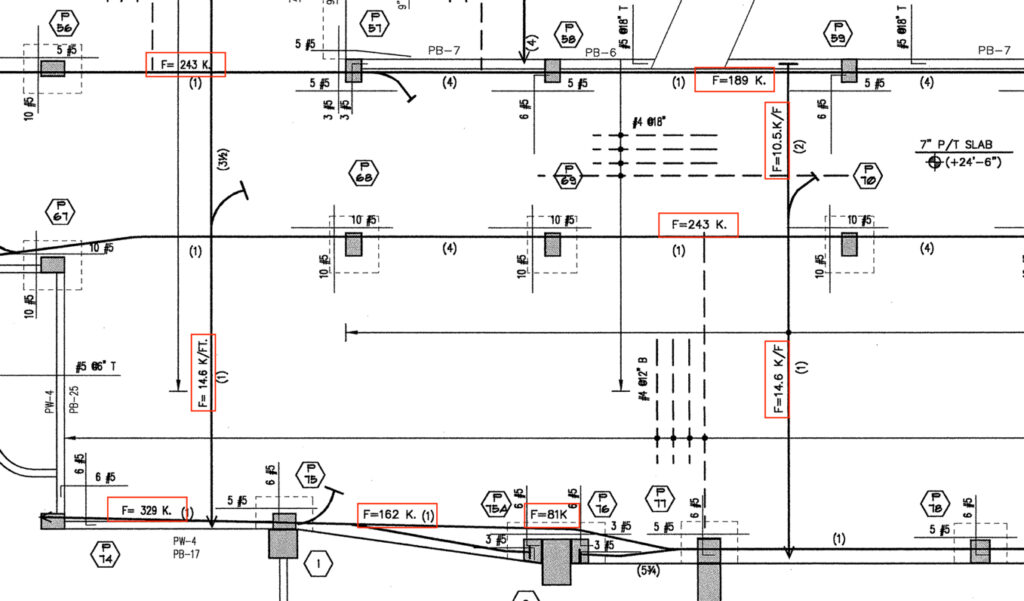

While the post-tensioned shop drawings dating to when the building was constructed can be extremely helpful in this process, should they not be available, the building structural plans can be nearly just as useful. The post-tension shop drawings provide a greater level of detail, but the specifier should become familiar with how much of this same information may be communicated in the structural plans. Many times, the design engineer will provide the posttensioning requirements by using notations such as “F=13k/ft” to designate the need for uniform tendons to be distributed at a roughly 2’ on center spacing. Likewise, a notation of “F=270k” would be an indication that there could be approximately 10 tendons located on a given band tendon span. These notations will also help to identify load changes within a given span, which would indicate the existence of add tendons within a section of the structure. This information can help the specifier identify the quantity and location of tendons as they relate to the location of the concrete structural damage.

Image 1: Post-tension load requirements noted on a structural plan.

Common Bid Form problems

Ultimately, the project Bid Form should be a concise summary of all scopes of work that have been outlined in the project plans and specifications. Therefore, each individual bid item should be sufficiently detailed and described in these documents to establish a clear understanding between all parties as to exactly what each bid item entails. However, experience has shown that there is often a disconnect between the work that is described in the bid form and the details provided in the project plans and specifications. The following is a summary of some of the most commonly found Bid Form issues:

- Individual Bid Form items don’t match plan details and/or specification descriptions:

This issue can seriously undermine the integrity of the entire bid process. In order for all parties on the project to have a clear understanding of exactly what scopes of work are being bid (and performed), there should be clarity and uniformity with the way each individual work items are conveyed in the bid form, and the descriptions used elsewhere in the Plans and Specifications. There shouldn’t be any inconsistencies, ambiguities, or incorrect terminology used with the scopes of work that are itemized in the Bid Form.

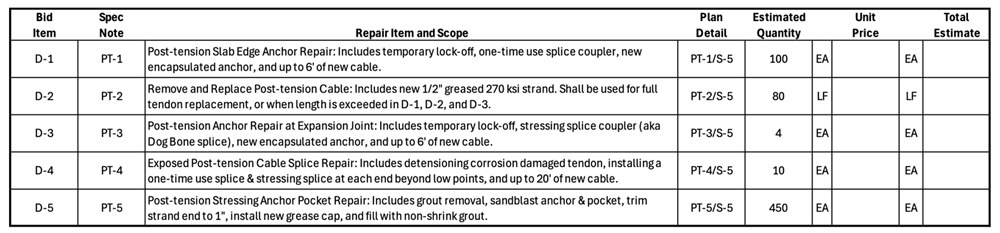

Image 2: Example of a Bid Form section with a list of post-tension repair scopes of work.

- Breaking up scopes of work that can’t be performed independently: Individual bid items should represent a comprehensive scope of work and should include everything that is integrally associated with the completion of that particular work item. While it is reasonable to break up some types of work, because while they may be associated with a given repair, they can also be quantified and performed independently. This includes work such as structural shoring, or the removal and replacement of concrete necessary to perform the post-tension repair. What should be avoided is to break up individual elements of a given repair, such as the tendon lock-off, splice installation, and anchor replacement, and create separate bid items for each. Since none of these items can be performed independently of each other, they are more representative of a schedule of value breakdown, rather than actual individual scopes of work.

- Using incorrect units of measure: This issue is more often associated with the replacement of post-tensioned cables as a scope of work. A common error is for this work to be bid on a per each basis, rather than per lineal foot. The problem is that specifiers will rarely provide the tendon length that forms the basis of this unit of measure, which creates confusion because each structure is comprised of many individual tendon spans of different lengths.

Assuming that a length is specified, the parties are then locked into this fixed length of tendon, and unless there is a mechanism for adjustment to account for the replacement of tendons of another length, this can be unfair to both the post-tension contractor and the building owner. That’s because if the actual length of tendon replaced is less than the bid length, then the owner will be paying for work that never happened. Likewise, if the actual length is greater than the bid quantity, then the contractor is not being fairly compensated for the actual labor and materials required to replace the longer tendon. That’s why using the lineal foot unit price basis has been found to be the most equitable way of bidding this work, because the contractor is fairly compensated for their work, and the owner only pays for the actual quantity of work performed.

- Bid item quantity estimates are unrealistic and prove grossly inaccurate:

We have seen this issue play out on both sides of the spectrum, where the quantity of work that was initially established in the bid estimate is considerably higher or lower than the actual quantities completed. This can create problems for both the building owner, as well as the contractor. From the contractor’s standpoint, most bid items will include both direct and indirect costs. When the project bid quantities are grossly overestimated, then the actual quantity may not be sufficient to cover all their fixed indirect costs.

The problem can be more significant for the building owner. If the quantity of work performed is less than estimated, then there’s generally no harm done. It’s when the quantities are substantially underestimated that larger problems are created. Depending on what was budgeted, there may not be sufficient funds available to handle the cost overrun.

This is usually less problematic when the project engineer has performed a suitable inspection of the structure and has been diligent in establishing a reasonable relationship between the visible concrete damage and the existing post-tensioning. It’s when the specifier’s efforts prove to be grossly inadequate that problems can arise. Unfortunately, there are too many instances when the post-tension repairs have no established bid quantities at all and are included only as a contingent unit cost. This means that the post-tensioned repairs can rapidly exceed the established project budget, which can have adverse consequences for all parties involved.

Project Specification problems

The Specifications can be a great opportunity for the specifier to provide a wide range of important information and requirements for the project. Unfortunately, we routinely find that there are a number of problems with the way the post-tensioned repair work is addressed in many project specification packages, and they generally fall into several categories:

- Place burden of the repair design and engineering on the contractor: While it is recognized that not every engineer has extensive experience repairing post-tensioned structures, it is incumbent on them as professionals to recognize if the scope of damage exceeds their capabilities and they should consider not accepting the project. Unfortunately, too many engineers won’t acknowledge this, but will rather pass on their responsibilities to a specialty post-tension contractor. Not only could this be viewed as unprofessional, but in many jurisdictions, it may also be illegal unless the contractors are also licensed engineers or retain one for this purpose. This often happens when the engineer issues an inspection report that suggests getting the advice of an experienced post-tension contractor, rather than providing detailed repair recommendations.

- Failure to address the post-tensioning in the Specifications: Should the specifier neglect to include suitable information that provides guidance for how the work should be performed, then the individual parties are left on their own to sort out how the post-tensioned repairs will be undertaken. Obviously, this could create problems depending on the capability and trustworthiness of the contracting parties.

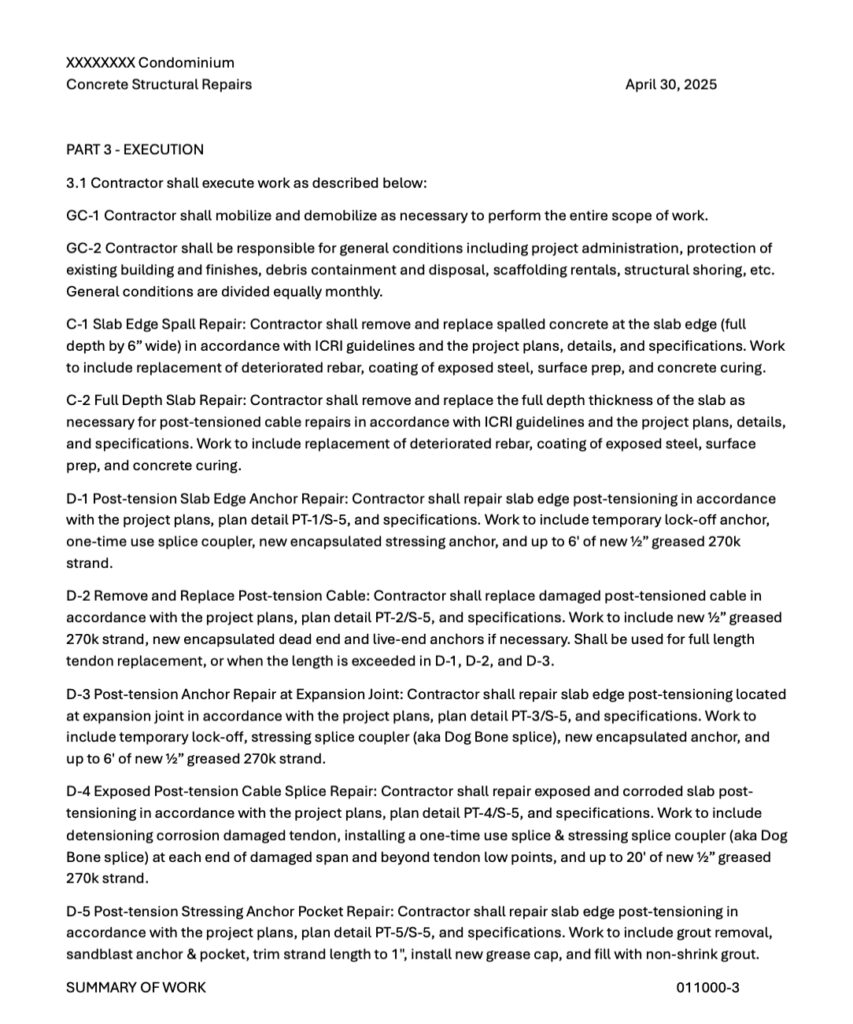

- Summary of work items are not adequately defined in the specification: A critical element in any bid package should be the use of consistent and uniform descriptions for each of the individual scopes of work that are being bid. When it is left to each party to interpret the specifier’s intended requirements and limitations for individual scopes of work, this can lead to misinterpretation and problems. To help avoid this, it’s recommended that the specifications include a brief summary of each work item with sufficient detail to provide a clear understanding of what is required. The Summary of Work included below is an example of one way to provide an outline that can help to establish a general understanding of what each individual bid line item represents.

Image 3: Example of specification summary of work descriptions.

Requiring new construction Project Submittal information for a repair project:

While often overlooked or ignored by both the engineer and contractor as ‘boiler plate’ language, there are instances when a submittal requirement in the Specifications or Plan notes can become a contentious obstacle. This usually happens when there are requirements in the bid documents for the contractor to provide services and/or documentation, which while routine and appropriate in new post-tensioned construction, may not be applicable, and sometimes impossible to provide on a post-tension repair project. It is recognized that there are submittal requirements which can be applicable to both new post-tensioned construction and repair projects, such as product data, contractor qualifications, equipment calibration, and stressing logs. However, the requirement for engineered shop drawings including tendon elevations and layout, installation procedures, wobble, curvature, tendon stressing requirements, and even elongation calculations, are usually not an appropriate contractor submittal for repair projects. That is unless there will be the planned removal and replacement of concrete structural sections of sufficient size that warrant the reestablishment of the preexisting tendon layout within the original structure. Even then, we contend that this information is more appropriately the responsibility of the project engineer of record and not the contractor.

Additionally, the request for elongation calculations is often negated by the fact that many repairs utilize one or more splice couplers and typically include relatively short lengths of new cable. Under these circumstances, the attempt to calculate the elongation required during tensioning is complicated by the short effective cable lengths, as well as movement associated with seating of the wedges in the splice couplers. Therefore, if the PTI protocol for measuring elongation is used, these repaired tendons may be observed to have sustained excessive elongation during tensioning. This is recognized to some extent by the PTI; in section 4.4.7.4 of the PTI Post-Tensioning Manual – Seventh Edition (TAB.1-23), it’s advised that for tendons less than 40 ft in length, the elongation shall fall within 7% + 1/4 in. of the theoretical elongation. It also cautions against overstressing tendons to achieve the calculated elongation.

Common problems found in the project Plan documents

The project Plans are a great opportunity for the specifier to provide useful details that will help to illustrate the individual post-tension repair scopes of work that have been itemized in the Bid Form, but this is sometimes overlooked.

Plan Notes:

While these are generally used by the specifier to provide useful guidance for the contractor and to outline many of the overall procedural requirements related to the project posttensioning, they can also serve as an opportunity to provide more detailed information for each type of individual post-tensioned repairs that will be required on the project. This can be particularly useful if these details haven’t otherwise been included elsewhere in the project Bid Form or Specifications.

Plan Details for individual post-tensioned repair scopes of work:

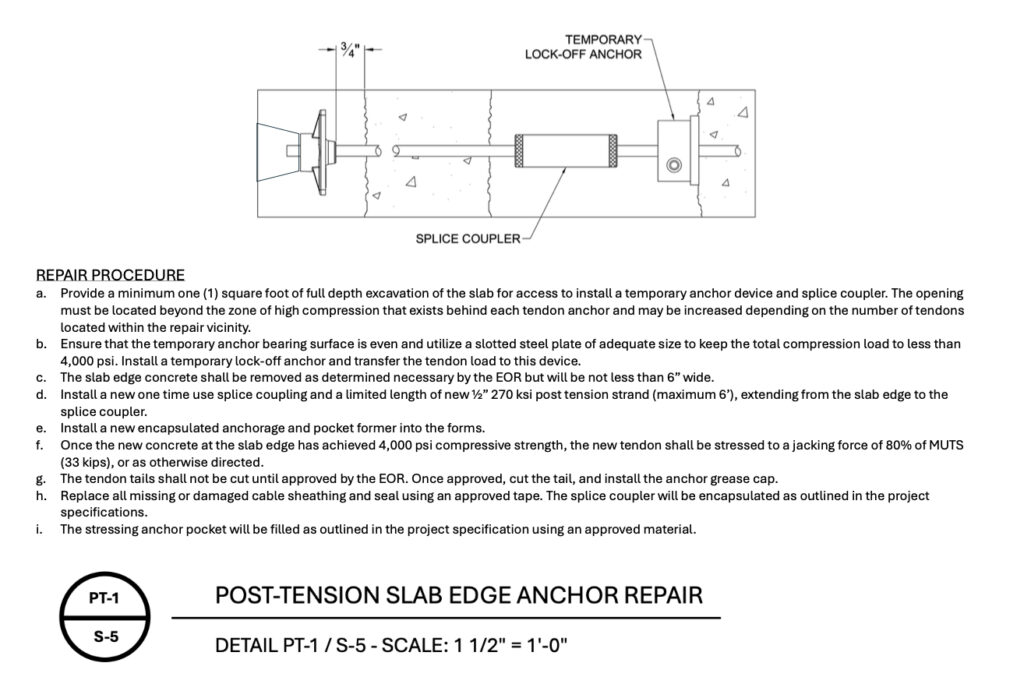

It is recognized that there can be important post-tensioning details that apply to more than one of the repair protocols, and it is certainly appropriate to include these details in the Plans. However, this is also an opportunity to reinforce the continuity and uniformity of the terminology that’s used elsewhere in the Specifications and Bid Form. A simple way to do this is to utilize the titles and alphanumeric identifiers of each of the individual repair protocols that are used elsewhere in the project documents. This should include the scope of work title, along with the Plan detail and page number, such as in the example included below for the Post-tension Slab Edge Anchor Repair PT-1/S-5. This will serve to create continuity throughout all the bid documents that will help to ensure there is a common understanding of the work required for each repair protocol. Lastly, one should avoid including repetitive and generally meaningless post-tension information that really serves no particular use or relevancy to the overall repair and acts more as page filler material.

Image 4: Example of bid scope of work detail in the project plans.

Conclusion

With over 30 years of experience in post-tensioned structural repairs, we have found that the reliance on ‘boiler plate’ bid documentation may be expedient in helping to get the package out the door, but the confusion caused by poorly prepared documents can lead to problems throughout every phase of the project. The preceding observations and recommendations are intended to provide specifiers with constructive and hopefully useful information regarding problems that are routinely encountered during the bidding and execution of numerous posttensioned repair projects from a contractor’s perspective.

For more information:

Please email us at info@GenBuild.net